The State Mints of Baden-Wuerttemberg produce circulation coins and high-quality commemorative coins on behalf of the Federal Republic of Germany and the central banks of other countries.

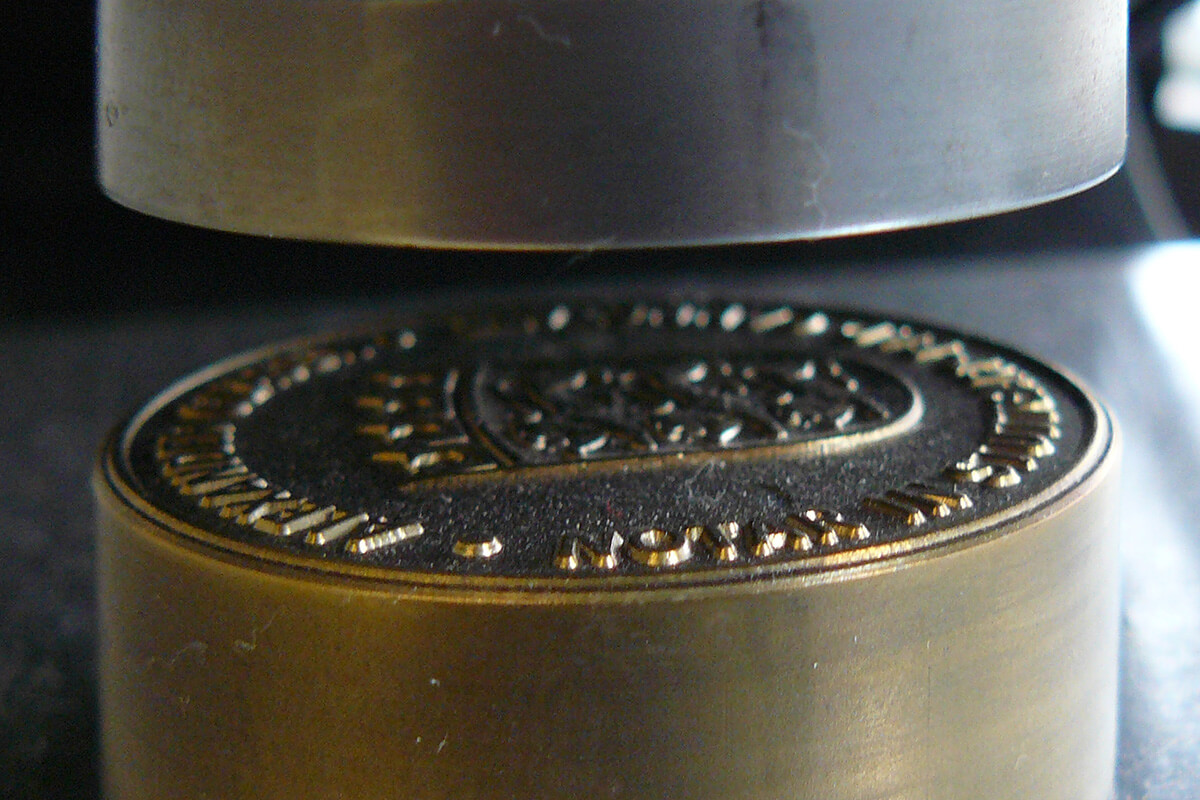

In that capacity, we offer bespoke advice on coin design, technical specifications and security features. We produce minting tools and dies and offer blanking, joining, edge lettering, minting and packing, as well as comprehensive logistical services including secure delivery to our clients. Of course, we also offer each production step as an individual service.